T.07-20,2022

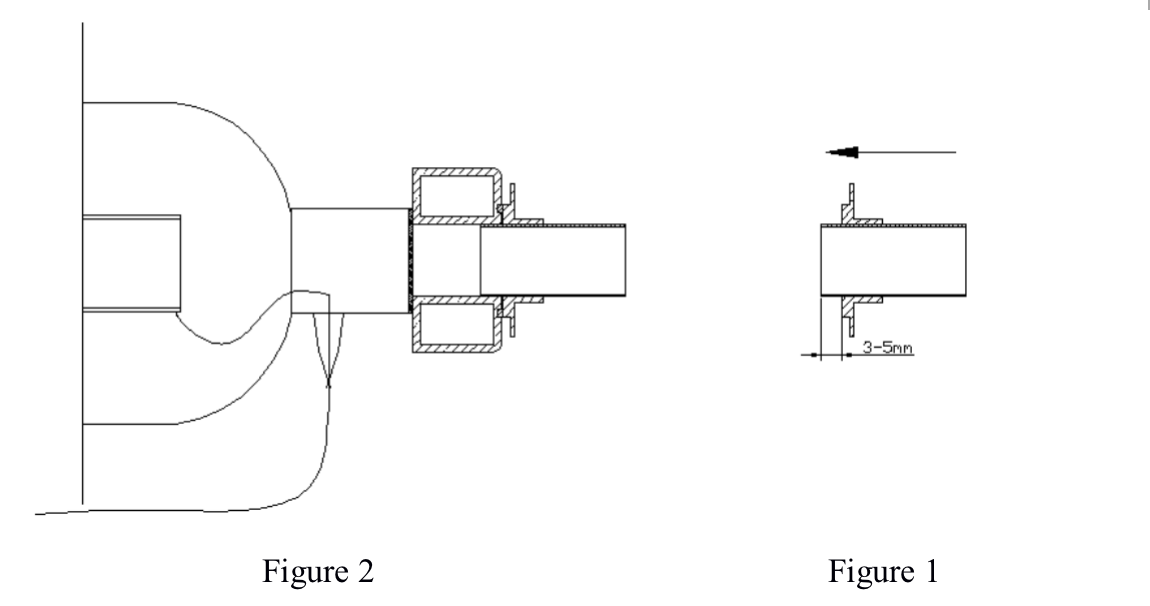

CO2 laser tubes are widely used in processing PVC, composite board, medium density fiberboard, plywood, leather and other materials,in which oily fume and dust may be generated. Such fume and dust may pollute the lenses, and thus affects the output power of the laser tubes. On the other hand, frequent wiping may cause scratches on the lenses. Therefore, users shall install a dust-proof tubes on the laser tubes to reduce the pollution and the frequency of wiping the lenses when using the laser tubes in harsh environments.

- Installation Instruction

- Installation Steps

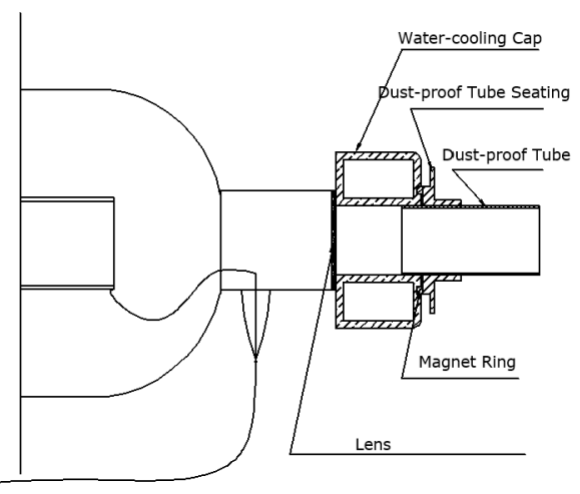

Step 1: Insert the dust-proof tube into the seating. The dust-proof tube shall extend 3-5mm beyond the bottom of the seating, shown in Figure 1 (already installed before delivery). Each CO2 laser tube is sold with a 30mm dust-proof tube, and customers can also upgrade the dust-proof tubes by choosing the 50mm and 100mm dust-proof tubes.

Step 2: Install the dust-proof tube on the water-cooling cap at the laser output window end of the CO2 laser tube. shown in Figure 2. The dust-proof tube will be automatically mounted on the water-cooling cap due to the effect of the magnetic ring.

Step 3: After installation, ensure that the dust-proof tube does not loose or block laser beam before turning on the laser tube.

Step 4: When the lens is dirty, remove the dust-proof tube first, and clean the lens by a cotton swab with absolute ethanol. After cleaning, install the dust-proof tube on when the absolute ethanol is completely volatilized.