T.07-04,2022

- Principle

Stress in the glass will be generated when the glass is under external force. The greater the external force (before the glass breakage), the greater the stress. The stress in the glass can be measured by the stress meter. When the status of the glass and the external force are under the same condition, the same stress shall be observed via the stress meter.

- Equipment

Stress meter for glasses;

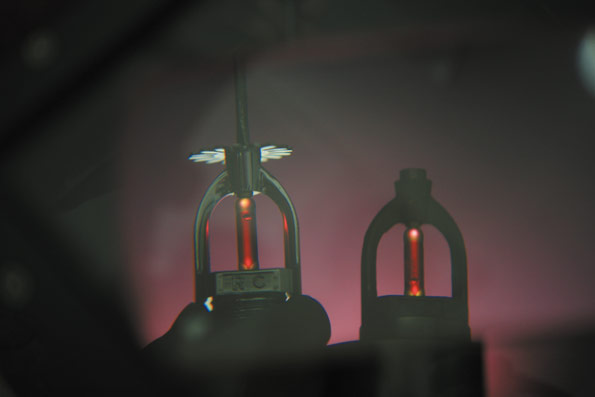

stress gauge mounted with sprinkler heads.

- Process

Install the sprinkler bulb in the sprinkler head mounted on the stress gauge. Turn on the light of the stress meter. Put the stress gauge on the working surface of the stress meter. The stress gauge shall be parallel to the working surface.

Tighten or loosen the screw on the top of the sprinkler head. Observe the stress shown on the stress gauge and the color change within the sprinkler bulb. The change of the stress can be reflected by the change of the color.

Keep the tested sprinkler bulb unchanged, and set another sprinkler head on the working surface. Users shall be able to figure out the stress applied on the sprinkler bulb by comparing the color and filter the unqualified sprinkler heads.

- Advantage

Non-destructive: the sprinkler heads will not be damaged.

Quantitative: the precision of the external force measurement can be controlled with ±25N (when f < 1000N).

Simple: the required equipment is easy to obtain, and the test methods are easy to process.

High efficiency: the testing process is efficient, making it possible for sprinkler manufacturers to achieve full inspection of their products;

- Requirements

All the testing sprinkler bulbs shall be from the same batch;

all the sprinkler screws shall be qualified and from the same batch;

the observing position shall be the spherical end of the sprinkler bulbs.

- Range of application

All the types of φ5mm & φ3mm sprinkler bulbs of Weeson Tech.